Oxy Acetylene Cutting Tip Selection

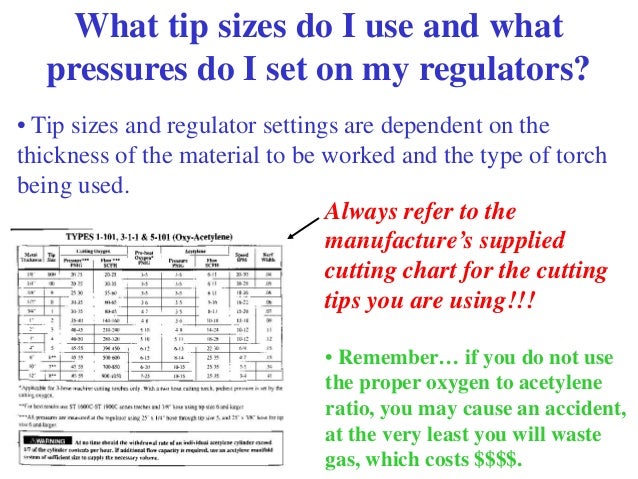

Up to 1 32 000 75 022 3 5 3 5 1 2 1 16 3 64 00 70 022 3 5 3 5 1 3 1 32 5 64 0 65 035 3 5.

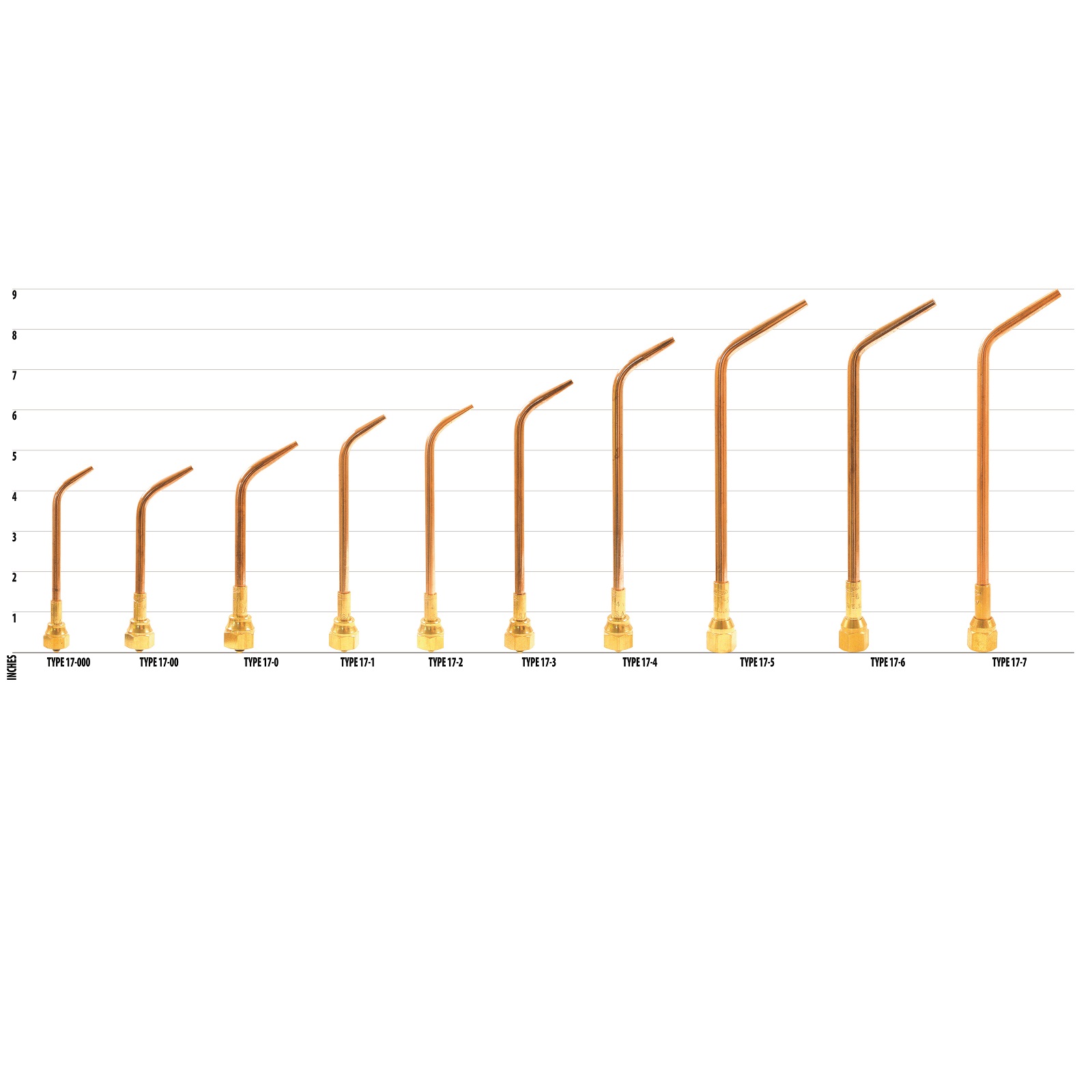

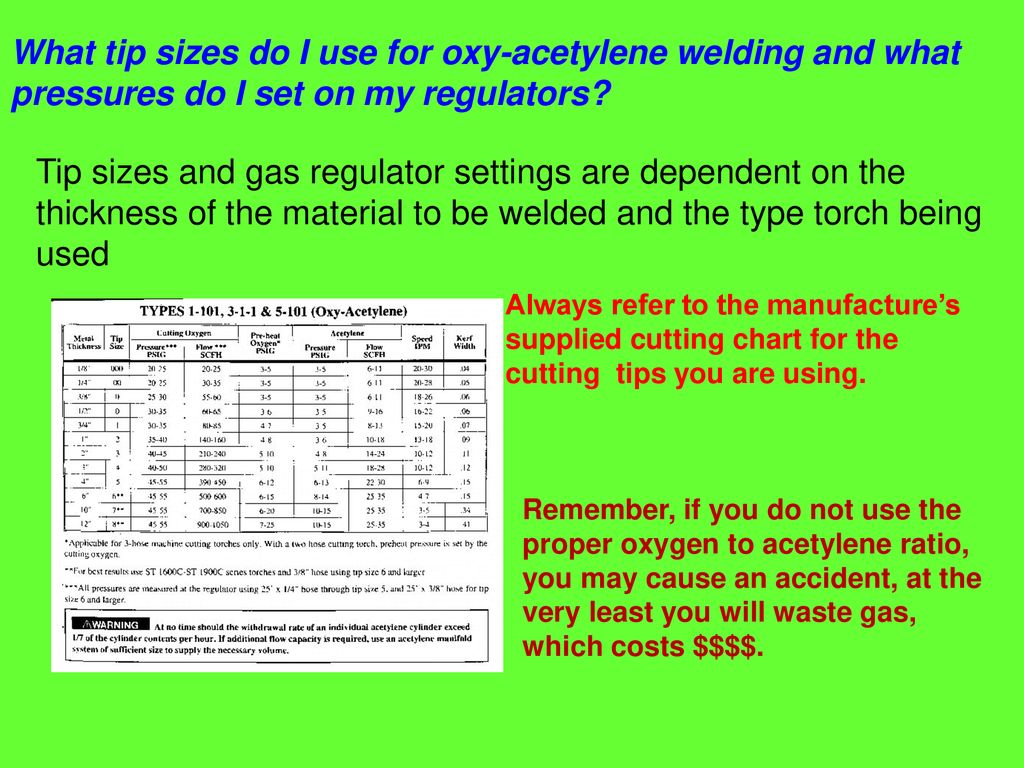

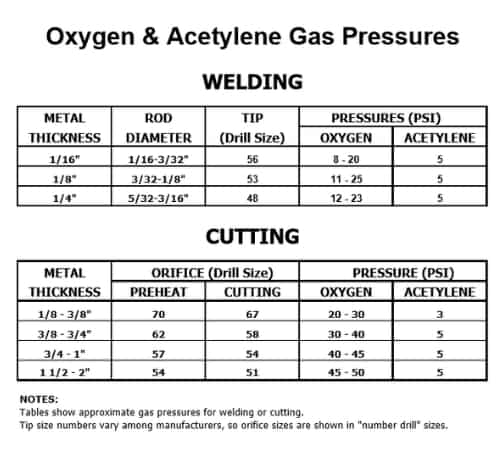

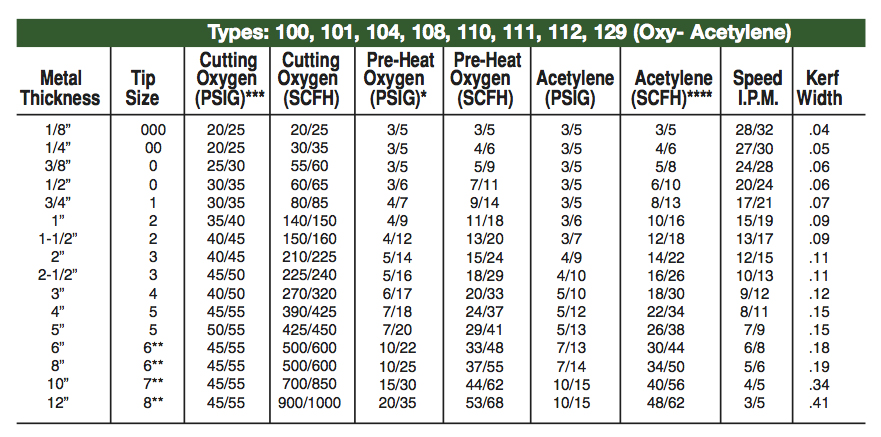

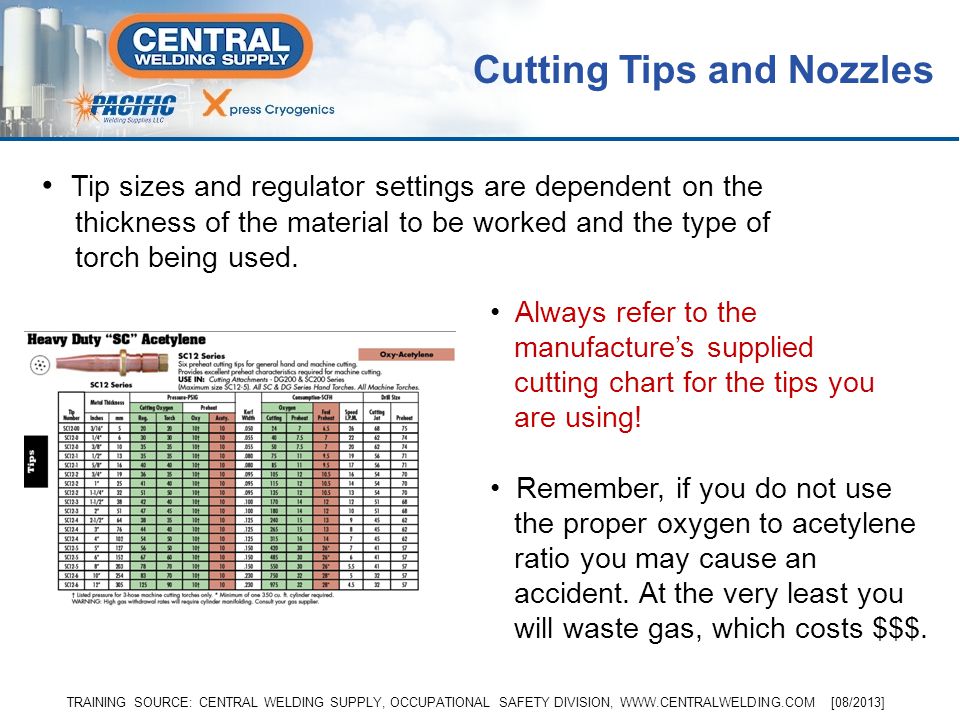

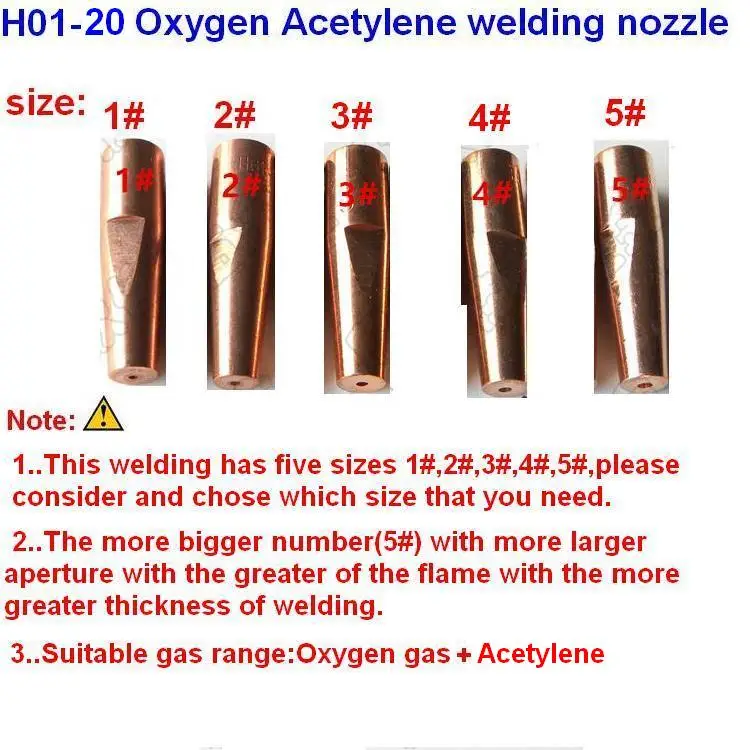

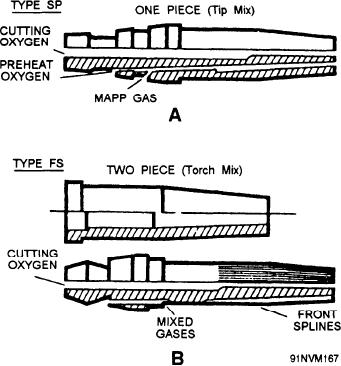

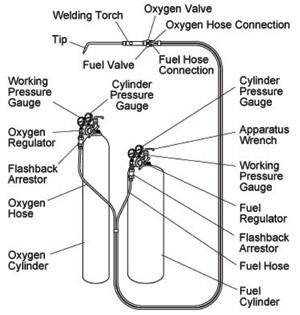

Oxy acetylene cutting tip selection. Cutting tips come in one piece and two piece styles. 1 16 of 463 results for oxy acetylene tips price and other details may vary based on size and color ally tools professional large and small 13 wire oxy acetylene tip cleaner set for cleaning welding cutting nozzles tips gas orifices engine carburetors sprinklers and shower heads. A 1 piece tip is typically used for oxygen acetylene use and a 2 piece tip is used for oxygen alternate fuel gas natural gas propane propylene etc use. Cutting tip designs vary based on fuel gas and application.

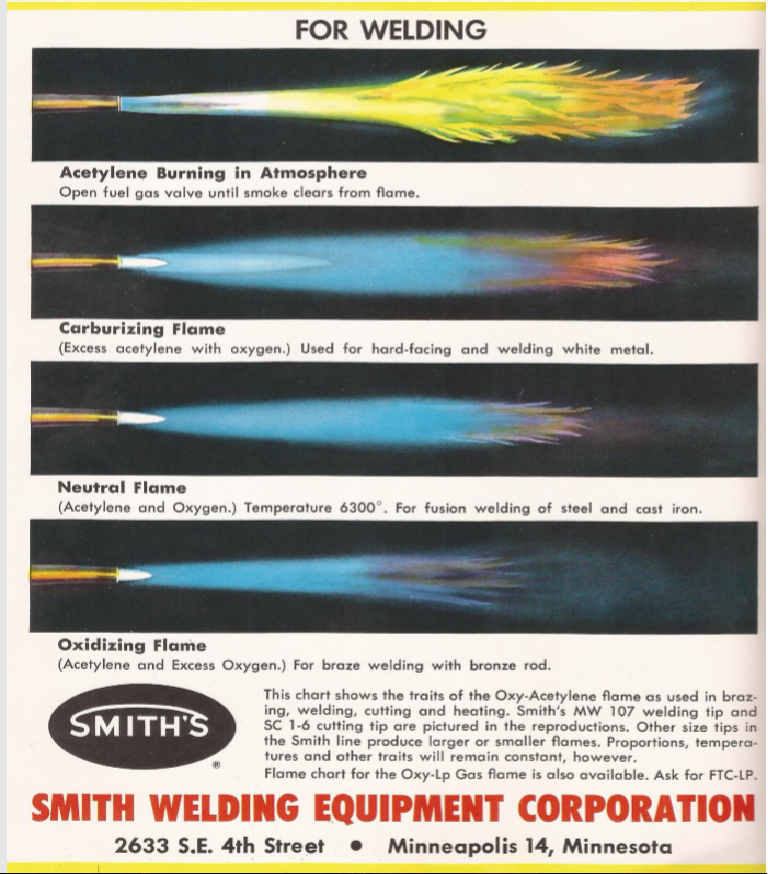

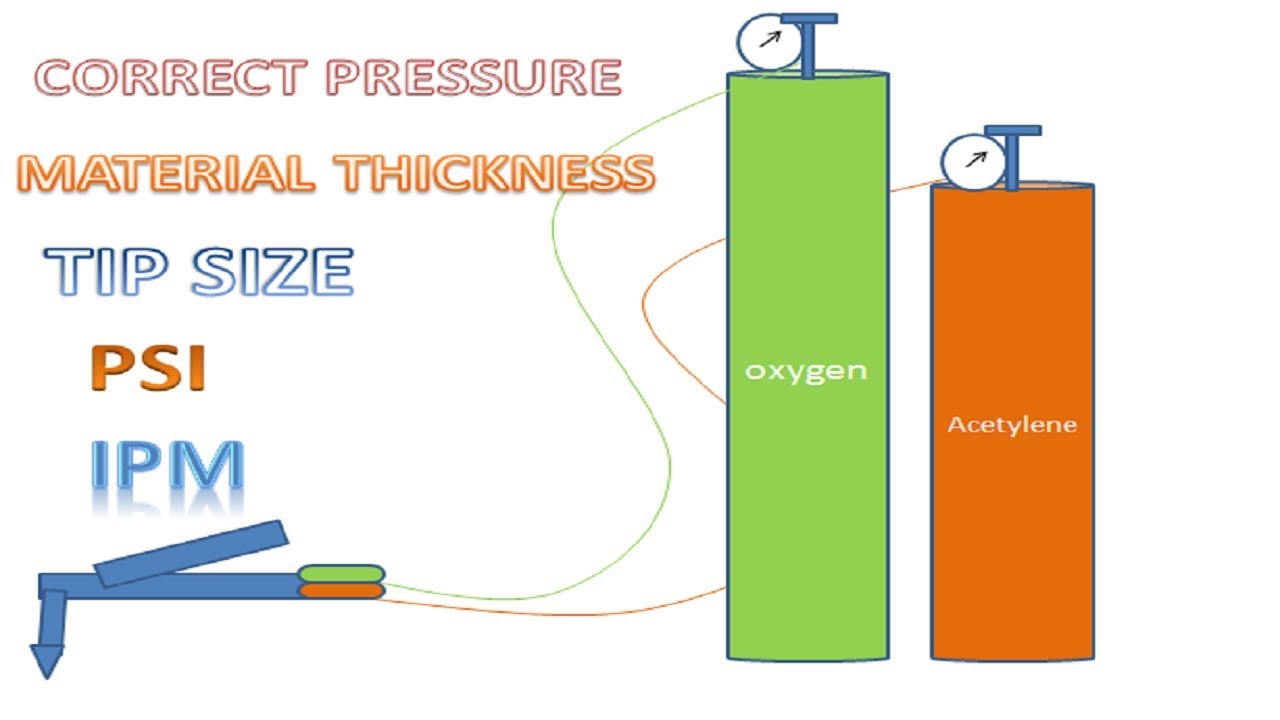

The copper alloy is machined drilled and. While using a cutting torch is easy in theory many people find it difficult to properly use let alone make a proper cut. Tip design is based on the flame characteristics of the fuel gas used as well as the intended use of the cutting tip. When designing or selecting an oxy fuel machine torch cutting nozzle tip one must consider several factors.

25 7 1 oxy fuel cutting principles 7 2 tip selection 7 3 cutting steel 7 4 piercing steel 26 ting progresses and make sure that the flow of slag is clear and not blocked. Move the torch in a straight line to keep a straight cut and move the torch at a uniform speed at which the flame is cutting through the metal. Select the tip style for the fuel gas you are using and metal type condition. One piece tips are used with acetylene and are made from copper alloy to withstand the heat of the cutting process see figure 2.

Part 1 of a 2 part series. 11 2 heating tips 37 11 3 preheating area and point of measurement 38 12 0 gas cutting 40 13 0 oxy fuel cutting procedures 42 13 1 cutting attachment operation 42 13 2 setting up 43 13 3 lighting up 44 13 4 closing down 45 14 0 oxy acetylene cutting techniques 46 14 1 how it works 46 15 0 using the cutting assembly 48.